You are here

Transfer of Defence Technology: Moving beyond Self-Reliance towards Technological Superiority

Transfers of technology (ToT) have been an important contributing factor to the building of capability in India’s defence industrial base. From as far back as the 1950s, numerous contracts with foreign firms have enabled the production of vehicles and guns, followed by main battle tanks and infantry combat vehicles, fighter and trainer aircraft, frigates and submarines, in the state-run production agencies (PAs) comprising of ordnance factories (OFs) and defence public sector undertakings (DPSUs).1 A sizeable thrust on developing indigenous defence technology was simultaneously spearheaded by the Defence Research and Development Organisation (DRDO) from the 1950s, although it has been constrained by a meagre budget. Despite this thrust, however, progress towards self-reliance in defence technology has not reached the milestones that were set apparently because global developments in defence technology outstripped the pace at which DRDO was able to advance.2 The Indian defence forces thus continue, as in the past, to depend on imported, globally competitive, defence systems.3 Given the collusive threats from neighbouring adversaries, one of which dwarfs India in economic and military strength, India needs to have commensurate equipment to face down these threats.4 China moreover is likely to possess in the future defence systems of high performance and lethality based on technology close to the leading edge.5

Transfers of technology (ToT) have been an important contributing factor to the building of capability in India’s defence industrial base. From as far back as the 1950s, numerous contracts with foreign firms have enabled the production of vehicles and guns, followed by main battle tanks and infantry combat vehicles, fighter and trainer aircraft, frigates and submarines, in the state-run production agencies (PAs) comprising of ordnance factories (OFs) and defence public sector undertakings (DPSUs).1 A sizeable thrust on developing indigenous defence technology was simultaneously spearheaded by the Defence Research and Development Organisation (DRDO) from the 1950s, although it has been constrained by a meagre budget. Despite this thrust, however, progress towards self-reliance in defence technology has not reached the milestones that were set apparently because global developments in defence technology outstripped the pace at which DRDO was able to advance.2 The Indian defence forces thus continue, as in the past, to depend on imported, globally competitive, defence systems.3 Given the collusive threats from neighbouring adversaries, one of which dwarfs India in economic and military strength, India needs to have commensurate equipment to face down these threats.4 China moreover is likely to possess in the future defence systems of high performance and lethality based on technology close to the leading edge.5

Achieving self-reliance in defence technology has been a national goal pursued by India from the mid-1960s.6 It was quantified by the Dr A.P.J. Kalam committee in 1992 by introducing the Self Reliance Index (SRI), which indicated the proportion of indigenously procured content against the total.7 Successive committees over the last two decades have laid targets of 70 per cent. But vigorous efforts made to ‘indigenise’ a larger number of foreign parts of the various systems being manufactured have been to no avail.8

The moot question is this: even if an SRI of 70 per cent were to be achieved, would it make any difference? India would still remain dependent on imports for the remaining 30 percent of parts and, when it comes to defence systems in use, the absence of even a vital one per cent, let alone 30 per cent, can render them ineffective. Such a situation can be avoided through local production of operationally vital materiel such as ammunition, fuel and some frequently needed spare parts, while the sporadic need for the remainder can be scientifically predicted, stocked and replenished in sufficient quantities. Assuming that events which might interrupt such replenishments and the supply of parts needed for production, such as the collapse of the Soviet Union and sanctions post the 1998 nuclear tests, are somewhat improbable in the future, and if defence systems are replaced timely with a determined periodicity by the next superior generation, is there a real need to stress on the level of self-reliance and the SRI achieved?

With the opening of the defence industry to the private sector in 2001, the Government of India (GoI), promulgated the Defence Procurement Procedure (DPP) in 2003 (last revised in 2016) and, subsequently, the Defence Production Policy (DPrP) in 2011, to guide acquisitions and production of defence systems. Since production also involved ToT from foreign firms, suitable clauses were provided to ensure their execution for maximum national benefit. Many of the national goals related to ToT, communicated in these two documents, overlap while some are unique to each. In the table below, excerpts conveying the goals or subsidiary objectives have been listed and short descriptions in brackets have been added to summarise and represent their contents:

| Goals conveyed by both documents | Goals conveyed through the DPP | Goals conveyed through the DPrP |

|

‘Substantive self-reliance in design, development and manufacturing in defence sector, in as early a time frame as possible’9 10 1112 ‘ensure increased participation and development of the Indian industry’13 14 ‘needs of the armed forces being a non-negotiable and an uncompromising aspect,15 the overall aim of ensuring that our forces have an edge over our potential adversaries at all times – in immediate terms as well as in sustainability – will be ensured’16 |

‘To improve efficiency of the procurement process’17 (Efficiency) ‘maintaining highest standards of transparency, probity and public accountability, fair competition and level-playing field’18 (Probity) ‘a balance between competing requirements such as expeditious procurement, high quality standards and appropriate costs’19 ‘comprehensive Transfer of Technology (ToT), pertaining ‘to give a complete exposure to them on design practices of OEM’ 21 ‘the technology absorption levels agreed to while concluding ToT contract have been achieved’ 22 |

‘Sub-systems/ equipment/ components that are not economically viable or practical to be made within the country may be imported, ensuring their availability at all times’23 ‘addressing any issue which impacts the competitiveness of the Indian defence industry in comparison to foreign companies’24 ‘producing state of the art defence equipment/ weapon systems/ platforms within the price lines and timelines are globally competitive' 25 |

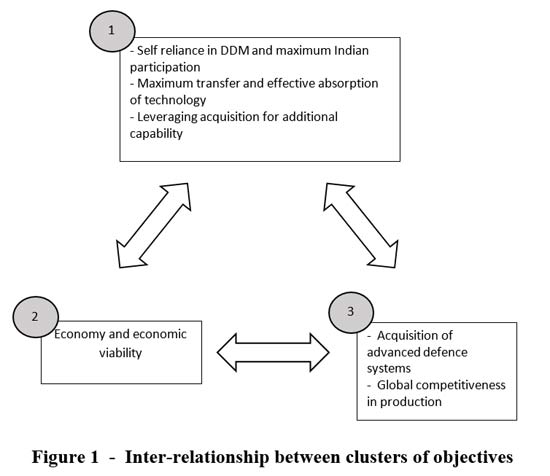

Leaving out the neutral objectives of efficiency and probity, the objectives which support each other can be grouped into three different clusters. And in the pursuit of the objectives (through ToT), each cluster adversely affects those of the others. A schematic of this inter-relationship is shown at Figure 1 below.

To elaborate, the objectives of Cluster 1 essentially require more technology and capability, which, in turn, will cost more, thereby impacting the economy objective of Cluster 2. Further, achieving self-reliance translates to indigenisation or import substitution which does not always mean cheaper parts. In fact, there are parts which could be much more expensive to manufacture in India due to the lack of raw material/components/machinery and the low scales in which they are required. So attempting to achieve self reliance beyond a certain point will clearly go against the objective of economy. The objective of Cluster 3 requires advanced technology and global competitiveness, which again will cost more and impact upon the goal of economy. Then again, the acquisition of more advanced or newer technology in Cluster 3 also means a wider gap between the imported technology and the technological capabilities of domestic industry. This, in turn, means that less technology will be absorbed leading to more dependence and less self reliance.

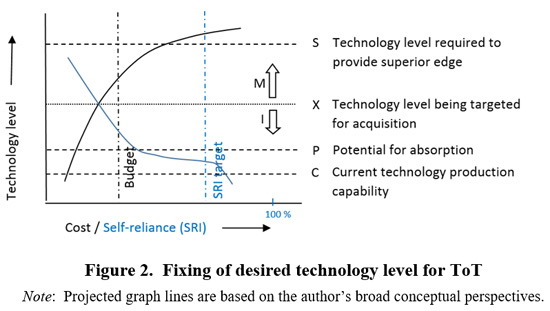

This triangle of goals, each pulling against the other two, can be further understood by the conceptual line graph in Figure 2 below.

The vertical axis indicates the technology level of a defence system in general, with the bottom representing, say, the technology of a third generation fighter aircraft and the top representing a sixth generation. Four levels — S, X, P and C within this range – are marked with horizontal dashed lines. The horizontal axis indicates two variables – the cost of the system in black and the SRI in blue. The black line graph indicates that as we look for more advanced technology to attain a greater military edge, the procurement cost increases exponentially.26 The blue line graph indicates that as we look for more advanced technology, the level of SRI achievable by industry is progressively lower since the gap between the technology being acquired and the potential for absorption increases. Conversely, if we opt for lower technology levels, the SRI achievable increases gradually at a steady rate till it reaches the potential for absorption and then increases quickly till it reaches a point where the remainder becomes difficult to indigenise as the foreign OEM will not part with proprietary components or the component concerned is grossly uneconomical to manufacture indigenously.

So, while the military (arrow marked ‘M’) strives for more advanced technology to gain a military edge, the industry (arrow marked ‘I’) asks for lower technology to achieve greater SRI. This phenomenon becomes evident from the statement of the Narendra Sisodia Committee of 2007, which pointed out that the Qualitative Requirements (QR) set by the defence services were aggregated from several systems in the global market and beyond the minimum capability needs, and involving the domestic industry would promote self-reliance by projecting realistic requirements in keeping with its potential.27

So, what is to be done? One solution to this conundrum is to raise levels C and P, that is, the technology levels that can be produced and the potential to absorb, respectively, so that they come closer to level S. Production ToT or licenced manufacture contracts by themselves cannot enable this since they provide only the know-hows of manufacturing specific parts and systems. The know-whys of the design could possibly help, but these are either not provided or simply unaffordable. Also, the know-whys acquired for say, a missile with a range of four km may not provide enough knowledge to build a next generation missile of a higher range of say eight km, which would need lighter, stronger material and perhaps even a different propellant. Raising such levels, hence, requires a wide and deep knowledge as well as skills base, which does not get built up by a narrow focus on frugal engineering based indigenisation of foreign parts as propagated by the goal of self-reliance. Raising these levels is, however, possible as we shall see ahead, and if achieved to a sufficiently high level, provides the benefits of not only being able to absorb a larger quantum of higher-level technology but also offer opportunities for exports, thereby bringing in much needed profits. For exports, however, the industry will need to work towards building globally competitive production capability. Such action to develop global competitiveness cannot be inspired by the goal of achieving self-reliance but by that of achieving technological superiority.

Nations working towards achieving technological superiority assisted by technology transfers is not a new phenomenon. In the civil technology domain, in 2003, the United Nations Conference on Trade and Development (UNCTAD) published the collated findings of three case studies of successful ToT ventures, one of which was that of Brazil’s Embraer.28 In the introduction, the paper emphasises the importance of ToT by mentioning how economically weaker countries can only catch up if they learn from the experience and practice of the more advanced countries. The firms in the case studies all acquired technology through numerous means and successfully adapted them to local conditions. These means included licencing arrangements, collaboration with foreign firms, and foreign direct investment, all of which thrived on protection of intellectual property rights (IPRs) enforced by local regulation. Though each case described faced different paths and hurdles, all achieved success through a gradual leaning away from traditional import substitution, which was focused on meeting domestic demand, to achieving international competitiveness. Brazil placed a greater emphasis on mastering technology in a few areas, over obtaining a larger share of value addition or indigenous content. This was done by a combination of indigenous efforts at learning and building capabilities as well as taking external assistance of consulting services, technology agreements and even research by leading multinationals.

Of course, the success of the firms in the study could not have been possible without some initial government support and interventions, such as those related to protective tariffs, subsidised inputs and low exchange rates. But breaking into the global market ultimately needed internationally competitive products based on technological superiority. And since the risks of venturing into an unprotected global market were high, each firm forged alliances with foreign investors and suppliers for risk-sharing. In its conclusion, the UNCTAD paper stresses the importance of human resources development and domestic knowledge generation to become technology leaders and pioneers, thus acquiring a stronger bargaining position when entering into knowledge-sharing arrangements with foreign collaborators.

So, for bringing up the levels of C and P, the Indian defence industry needs to move up the capability curve through learning which is the key source of change and the most important mechanism for knowledge accumulation, innovation and growth. This can be facilitated first by interaction with other organisations dealing with such aspects as education, training, research and development (R&D), financing and policy support. And secondly, it can be facilitated by a national system of innovation founded on a strong IPR regime, which encourages, rewards and protects original innovators in a domestic competitive environment.29

A large part of technical learning can be facilitated by using indigenous R&D agencies. Embraer effectively used scientists of Brazil’s state-run Institute for Research and Development towards this end. Hence, if India decides to work towards technological superiority, the Department of Science and Technology and more significantly the DRDO, with its wealth of R&D knowledge, can play a vital role. Combining their strengths with optimally arranged foreign collaborations for profits, risk-sharing and a common goal of achieving technological superiority could well enable India to break into the global market in select areas. Such a breakthrough should then initiate a chain of other breakthroughs through the leveraging of greater bargaining power for technology-sharing with foreign collaborators. The Indian defence industry would then be able to deliver systems which the armed forces would find capable of meeting their needs.

Views expressed are of the author and do not necessarily reflect the views of the IDSA or of the Government of India.

NOTE: The last sentence has been rephrased to reflect the author's intended meaning.

- 1. Ron Matthews, Defence Production in India, New Delhi: ABC Publishing House, 1989, pp. 35–37. Also see, Laxman Kumar Behera, Indian Defence Industry: Issues of Self Reliance, New Delhi: Institute for Defence Studies and Analysis (IDSA), 2013, pp. 9–21.

- 2. Kevin A. Desouza, Transfer of Defence Technology to India: Prevalence, Significance and Insights, Journal of Defence Studies, Vol. 10, No. 4 October-December 2016, pp. 31-32, available at http://idsa.in/jds/jds_10_4_2016_transfer-of-defence-technology-to-india

- 3. “India world's largest importer of major arms in the last four years,” The Economic Times, 20 February 2017, available at http://economictimes.indiatimes.com/articleshow/57244332.cms?utm_source=..., last accessed on 27 July 2017

- 4. “Who is the bigger military power: China or India?, The Economic Times, 20 July 2017, available at http://economictimes.indiatimes.com/news/defence/who-is-the-bigger-milit..., last accessed on 27 July 2017

- 5. US DoD news, DoD Report: China’s Military Investments Continue, 13 May 2016, available at https://www.defense.gov/News/Article/Article/759522/dod-report-chinas-mi..., last accessed on 27 July 2017

- 6. Laxman Kumar Behera, Indian Defence Industry, op. cit., p. 34.

- 7. Ibid, p. 46.

- 8. “Reality bites make-in-India defence dream,” The Tribune, 3 February 2016, at http://www.tribuneindia.com/news/comment/reality-bites-make-in-india-def...

- 9. Government of India, Ministry of Defence, Defence Production Policy 2011, para 4

- 10. Ibid, para 2

- 11. Government of India, Ministry of Defence, Defence Procurement Procedure 2016, p. xi.

- 12. Ibid, p. III.

- 13. Ibid, p. ix.

- 14. Ibid, p. xi.

- 15. Ibid, p. 1.

- 16. Defence Production Policy 2011, para 2.

- 17. Defence Procurement Procedure 2016, p. III.

- 18. Ibid, p. 1.

- 19. Ibid, p. xi.

- 20. Ibid, p. 1.

- 21. Ibid, p. 136.

- 22. Ibid, p. 29.

- 23. Defence Production Policy 2011, para 4.

- 24. Ibid, para 5.

- 25. Ibid, para 6.

- 26. Initially, high procurement costs of advanced technology can however be partially ameliorated by higher reliability induced lower life-cycle costs.

- 27. Behera, Indian Defence Industry, p. 66.

- 28. UNCTAD, Transfer of Technology for Successful Integration into the Global Economy, 2003, pp. 3-24, at http://unctad.org/en/docs/iteipc20036_en.pdf

- 29. UNCTAD, Transfer of Technology for Successful Integration into the Global Economy, p. 27.

| Attachment | Size |

|---|---|

| 320.68 KB |